For over thirty years, Olivine has been perfecting the art of taking a problem and turning it into a profit. They are the manufacturers of one of the world's leading gasification burner technologies - a technology so advanced that it is capable of handling any and all waste products but still meets the most stringent environmental standards anywhere in the world!

Olivine has made dramatic improvements, particularly in the areas of computerization and flow control. By controlling the rate at which the waste is processed in the combustion chamber, Olivine ensures the most consistent temperature controls and, in so doing, ensures that there are no organic airborne pollutants released during the process.

The units are efficient, easily maintained, cost-effective, and rugged, while offering the highest environmental sensitivity possible.

We know that to be a successful solution to the waste disposal problems faced by municipalities around the world, the units must meet the following criteria:

- Low Initial Cost - we believe the lowest price for technology of this quality

- Ease of maintenance and operation

- Rapid parts replacement utilizing "off-the-shelf" availability

- Meet or exceed all EPA and US Department of the Environment (or similar) environmental standards for air and water emissions.

- Utilize the greatest possible percentage of the latent energy stored in the waste products and which would, otherwise, be lost if disposed in traditional landfills

These units feature a unique refractory material that can handle temperatures exceeding 2500 degrees F, with little or no maintenance, and the plants are literally capable of running 24 hours a day, virtually 365 days a year.

A constant temperature is maintained throughout the continuous burn by utilizing an under-fire fan system and automatic, computer controlled fuel feed, air lock, feed stock and ash removal systems. An over-fire fan introduces oxygen and imparts a circular motion to the gases and maintains them in the combustion chamber for approximately six seconds before they are drawn into the boiler system.

The boilers have been designed to handle municipal solid waste, including plastics that can condense and damage normal boiler tubes. The boilers are also computer controlled with manual bypass safety systems that meet all standards for safe and simple boiler operation.

The electrical system is built around a low pressure steam turbine generator set of 5-60 Megawatt (depending on waste volume processed) capacity. The plant is supplied complete with all synchronizing, transforming, load protection and switchgear for connection to a standard power line grid. All electrical systems are computer controlled.

Emissions and emissions control systems meet or exceed all EPA standards and guidelines for thermal processing facilities. A spray dryer removes acid gases from the exhaust and fine particles are removed in the bag house, where they are continuously monitored. A very sophisticated monitoring system measures, records and controls emission performance. The burner ash is quenched and prepared for either transport to a landfill or to be used in the manufacture of building blocks, road barriers, asphalt, etc.

Product Details

Our waste-to-energy systems are cutting-edge technology and are pleased to describe, in greater detail, the specific benefits your municipality or company would derive from their use.

It is generally recognized that the problem of disposal and/or treatment of municipal and commercial waste, in many urban areas, requires an efficient and economical solution, within the financial means available to those communities and their residential and commercial taxpayers. Most of the major urban centers, world-wide, have an immediate need for low cost, efficient, compact and turn-key waste treatment facilities compatible with local sanitation, power supply and financial capabilities.

We offer compact solid waste-to-electric power conversion units, using solid waste as the only source of energy.

The economic rationale and the expected high rate of return to be generated by these proposed waste-to-electric power conversion units are based on the following facts:

- The present economic environment of most developing countries and many communities in the United States and Canada requires a low cost solution to the ever-increasing sanitation and waste disposal problems.

- Most of the developing and developed countries' energy resources are composed, largely, of potential solid fuels such as agricultural wastes, forestry wastes, as well as industrial, municipal and medical wastes. Those resources have, traditionally, rarely been put to productive use.

- The increasing volume of municipal and industrial waste discharge in major urban centers is complicated by a lack of cost-effective methods of waste disposal and insufficient financial resources to deal with the implementation of modern environmentally sensitive solutions.

- The recent dramatic increase in oil prices has meant that diversification of energy sources would allow countries using oil for some or all of its domestic energy needs to allocate that fuel to other, higher value-added uses, by maximizing the reliance on biomaterial-based fuels and recycled materials.

- Most of the developing countries, as well as many developed countries, do not have significant hydroelectric capabilities and have limited access to other domestic energy sources.

In view of these considerations, plus the reality of increasingly restrictive environmental protection regulations, municipalities have relatively few alternatives that are as cost effective as solid waste conversion to energy. Given the ever-increasing sanitary problems facing most populated centers today, and the certainty of increasing energy costs and demand, the most efficient, profitable and environmentally sensitive conclusion is the construction of versatile waste-to-electricity power plants. These power conversion units are not only competitive compared to other types of electric generating plants that utilize hydrocarbon-based fuels, but, unlike coal or diesel plants, they will comply with the most restrictive environmental protection requirements anywhere in the world.

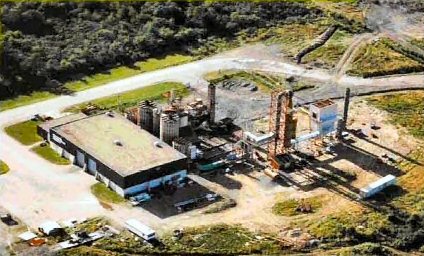

Typical 1,000 TPD Olivine plantThe technology of waste combustion technologies has been developed and refined by several North American and European companies to enable municipalities to satisfy all their waste disposal objectives, while operating within modern environmental constraints and requirements.

Typical 1,000 TPD Olivine plantThe technology of waste combustion technologies has been developed and refined by several North American and European companies to enable municipalities to satisfy all their waste disposal objectives, while operating within modern environmental constraints and requirements.

We can supply low cost municipal and/or agricultural waste-to-power plants for major population centers, on a turn-key basis. These plants, or batteries of plants, will operate independently and, by recovering the latent energy contained with the waste products, satisfy some or all of the energy needs of those municipalities. These plants can also be connected to the national, regional or local power distribution systems with no need for large fuel unloading terminals and transformation systems. The plant's energy use versatility allows the operators to use any local energy resources and, thereby, reduce the dependency on more expensive sources of fuel. The plant's size, and the technology used in these plants, ensures that all environmental considerations are met while dramatically reducing, or eliminating altogether, the need for traditional landfills.

For any municipality, these proposed waste-to-power conversion plants will generate and provide some obvious economic benefits, including:

- The power plant will produce permanent and temporary employment during the initial construction and operation periods.

- Provide economic solution to the ever-increasing municipal, industrial and, especially, medical waste discharge needs, jointly with the production of substantial electric power, necessary for the city and the region development, all at a rate comparable to the present real cost of energy production.

- Provide a nucleus of economic activity around a new power source, which can be a powerful tool for economic development.

- Reduce the local or national dependency on more expensive and/or foreign sources of energy, and, simultaneously, increase the value-added potential of the domestic or regional agricultural, food processing and other industries by using agricultural and urban waste.

- Minimizing, or eliminating, waste disposal problems and costs by using the residual ash for the production of cement construction blocks. This is accomplished by adding a small concrete plant provided to each unit or battery of units. The size and production capacity of each concrete plant would be commensurate with the plant ash production.

- Generation of income and tax revenues.

- Elimination of long-term ground water contamination from traditional landfill use

- Possible improved access to World Bank and other international aid programs designed to promote environmental protection

- Can be used in connection with recycling initiatives or, alternatively, the units can use plastic and paper waste products to maximize energy recovery.

The construction time is relatively short, given that our units feature "off-the-shelf" components and are available for immediate shipment and on site assembly.

See Partial list of recent installations world wide.

Our plants are designed to handle a minimum of 250 tons per day (TPD) of municipal or commercial solid waste, and, due to their modular design, they can be combined in batteries of one to twelve prefabricated 250 TPD units, able to satisfy any required capacity while maximizing energy recovery.

Our units boast the following advantages

- low installation, maintenance and operating costs

- capable of burning any solid waste of 50% combustible content

- complete combustion

- meet all air pollution standards, current and planned (US EPA)

- require no auxiliary fuel

- sorting, if required, can be done at the ash afterburner

- the most advanced technology available today

Equipment Supplied 250 TPD plant

(specifications increased appropriately for other configurations)

- primary chamber 23' diam. 42' high

- chamber feed chute

- refractory V-hearth

- walking floor

- ash house with timer and loader access

- hydraulic controls, manually operated

- over-fire blower 50HP

- under-fire blower 40 HP

- secondary chamber 21' diam. X 42" high

- high temperature refractionary

- refractory cross-over duct

- refractory duct to boilers

- boiler system including pumps

- refractory cooling, water tank with conditioner timer

- one (1) stack cooler and bag house

- control room including computer controls

- steel waste storage building and waste water tank

- unloading sump and conveyor systems

- paved and fenced yard

- lighting for yard and buildings

- powerhouse including turbine 5 Megawatt turbine per unit

- construction blocks production plant, for ash disposal

This complete unit, installed and ready for operation, includes the initial training of local personnel. Ongoing management can be provided, if desired.

Land Requirement

A typical 250 TPD Waste System requires two acres of land, a typical 500 TPD Waste System requires between three to five acres of land, typical 1000 TPD plant requires between five to seven acres of land.

View pictures of the Olivine Facility

Unless otherwise stated the following two sections (Implementation and Economics) refer to a Double silo model (500 tons per day TPD capacity), with multiple bag-house cleaners, V-hearth combustion, continuous feed and ash removal system, and indoor storage for a three day supply of waste.

Download the complete Waste to Energy proposal document